Manual Transmission Shift Linkage Diagram: A Comprehensive Guide

Navigating the intricacies of manual transmissions requires understanding the shift linkage, a vital system connecting the lever to the gearbox․

YouTube offers tutorials, while Google accounts enhance the user experience, and Premium subscriptions unlock additional features for dedicated enthusiasts․

The manual transmission shift linkage is a crucial component in vehicles equipped with a manual gearbox, acting as the intermediary between the driver’s shift lever and the internal shifting mechanisms within the transmission itself․ This system translates the driver’s intentional gear selections into the physical movement required to engage different gears․ Understanding its function is paramount for both drivers and mechanics alike․

Modern resources like YouTube provide visual guides and troubleshooting assistance, while a Google account integration streamlines the user experience․ Premium YouTube subscriptions offer ad-free viewing and background playback․ The linkage isn’t merely a mechanical connection; it’s a carefully engineered system influencing driving feel and precision․ Proper functionality ensures smooth, accurate gear changes, contributing significantly to overall vehicle control and enjoyment․ A malfunctioning linkage can lead to frustrating shifting issues, impacting performance and safety;

Understanding the Purpose of Shift Linkage

The primary purpose of a manual transmission shift linkage is to accurately transmit the driver’s gear selection from the shift lever to the transmission’s internal shift forks․ This precise movement engages the appropriate gears, enabling the vehicle to accelerate, decelerate, or maintain speed․ Without a functional shift linkage, changing gears would be impossible, rendering the vehicle immobile or severely limiting its operational capabilities․

Online platforms like YouTube offer detailed explanations and visual demonstrations of this process, while Google accounts provide personalized viewing experiences․ YouTube Premium enhances access with ad-free content․ The linkage must overcome resistance from synchronizers and gear teeth, demanding robust construction and precise adjustment․ It’s a critical system impacting driving enjoyment and vehicle safety, requiring regular inspection and maintenance to ensure optimal performance and prevent frustrating mechanical failures․

Types of Manual Transmission Shift Linkage Systems

Manual transmission shift linkages broadly fall into three categories: direct, cable-operated, and hydraulic․ Direct linkage, common in older vehicles, uses rigid rods directly connecting the lever to the transmission, offering a precise, tactile feel․ Cable-operated systems employ flexible cables, allowing for more remote lever placement and simplifying installation, often seen in front-wheel-drive cars․

Hydraulic linkages, less common, utilize fluid pressure to actuate the shift forks, providing smooth operation but adding complexity․ YouTube tutorials visually demonstrate each system’s operation․ Google accounts personalize search results for specific linkage types․ Modern advancements explore electronic systems, enhancing precision and responsiveness․ Understanding these differences is crucial for diagnosis and repair, as each system requires unique maintenance procedures and troubleshooting techniques, impacting driving experience․

Direct Linkage Systems

Direct linkage systems represent the most mechanically straightforward approach to transmitting driver input to the manual transmission․ Utilizing solid rods and pivot joints, these systems offer a very direct and tactile connection, providing precise gear selection and a satisfying mechanical feel․ Commonly found in older rear-wheel-drive vehicles, they require careful adjustment to eliminate slop and ensure accurate engagement․

YouTube videos showcase detailed examples of direct linkage construction and adjustment․ Google searches reveal common failure points, like worn bushings․ While robust, they are sensitive to chassis flex and require precise alignment․ Maintaining proper lubrication of pivot points is critical․ Though less common in modern vehicles, understanding direct linkage is fundamental for enthusiasts and mechanics, offering a pure driving experience․

Cable-Operated Linkage Systems

Cable-operated shift linkage systems represent a significant advancement over direct linkages, offering greater flexibility in transmission placement and reduced sensitivity to chassis flex․ These systems employ steel cables connected to the shift lever and transmission selector, transmitting motion through tension․ Widely used in front-wheel-drive vehicles and increasingly common in rear-wheel-drive applications, they provide a cost-effective and relatively simple solution․

YouTube tutorials demonstrate cable adjustment procedures, crucial for smooth shifting․ Google searches highlight potential issues like stretched or frayed cables․ Maintaining proper cable tension is paramount; too loose results in sloppy shifts, while too tight can cause binding․ Regular inspection for corrosion and damage is essential; While offering less direct feel than direct linkages, cable systems provide reliable performance and ease of maintenance․

Hydraulic Linkage Systems

Hydraulic shift linkage systems, though less common than cable or direct linkages, offer precision and a unique driving experience․ Utilizing hydraulic fluid within sealed lines, these systems transmit force from the shift lever to the transmission․ This design minimizes play and provides a consistent, often lighter, shift feel․ Often found in performance or luxury vehicles, they require a more complex setup and maintenance routine․

YouTube resources detail hydraulic fluid level checks and potential leak identification․ Google searches reveal concerns about fluid contamination and component wear․ Maintaining proper fluid levels and ensuring the system remains sealed are critical․ While offering superior feel, hydraulic systems are susceptible to leaks and require specialized knowledge for repair․ Premium YouTube subscriptions may offer in-depth diagnostic guides․

Components of a Typical Shift Linkage System

Essential parts include the shift lever, rods, forks, and the transmission input shaft, working in harmony for smooth gear changes, as detailed on YouTube․

Shift Lever and Knob

The shift lever serves as the driver’s primary interface with the manual transmission, translating intentional movements into mechanical actions within the linkage system․ Its design varies significantly, ranging from simple, straight levers to ergonomically curved designs intended to enhance comfort and control․ The knob, attached to the lever, provides a tactile grip for the driver․ Materials used for knobs span from basic plastic to premium materials like aluminum, carbon fiber, or even weighted spheres, influencing shift feel and aesthetics․

YouTube tutorials demonstrate how lever position directly impacts the selector rod movement, initiating gear changes․ A properly functioning lever should exhibit minimal play and smooth, precise movement throughout its range․ Google account integration with YouTube allows users to save favorite tutorials related to shift lever adjustments and upgrades․ Premium subscriptions unlock ad-free viewing for uninterrupted learning․ The lever’s connection point to the linkage is crucial; wear or looseness here can contribute to sloppy shifting․

Shift Linkage Rods and Joints

Shift linkage rods are the rigid connectors transmitting motion from the shift lever to the transmission selector․ Typically constructed from steel, these rods are crucial for accurate gear engagement․ Joints, including ball-and-socket or polyurethane bushings, allow for necessary articulation as the transmission moves with the engine and chassis․ These joints are prime locations for wear, leading to imprecise shifting and a vague feel․

YouTube provides visual guides on inspecting and replacing worn linkage components․ Google account access facilitates saving these helpful videos․ Premium YouTube subscriptions offer ad-free viewing during repair tutorials; Proper rod alignment is paramount; even slight misalignment can hinder smooth gear changes․ Regular inspection for corrosion, bending, or damaged bushings is essential for maintaining optimal performance․ Upgrading to polyurethane bushings, showcased on YouTube, can significantly improve shift precision․

Shift Forks

Shift forks are internal components within the transmission responsible for physically engaging the synchronizers to select different gears․ Activated by the selector rods, these forks slide along grooves to move the synchronizers into mesh with the desired gear․ They are subjected to significant force during gear changes, making them susceptible to wear and bending․

YouTube tutorials demonstrate transmission disassembly, revealing the location and function of shift forks․ Google searches quickly locate diagrams illustrating their operation․ Worn or damaged shift forks can cause difficulty selecting gears, popping out of gear, or grinding noises․ Inspecting forks during transmission service is crucial․ Premium YouTube access provides uninterrupted viewing of detailed repair procedures․ Replacement is often necessary when addressing transmission issues, and proper lubrication is vital for smooth operation, as highlighted in online repair guides․

Selector Rods

Selector rods are crucial intermediaries transferring motion from the shift linkage to the shift forks inside the transmission․ These rods, often connected via ball-and-socket joints, translate the driver’s gear selection into the necessary movement to engage the appropriate gear․ They experience constant stress and wear, impacting shifting precision․

Online resources, including YouTube videos, showcase selector rod placement and function during transmission teardowns․ Google searches reveal diagrams detailing their connection to the shift forks․ Issues like bent or worn selector rods manifest as imprecise shifting, difficulty finding gears, or a loose feel․ Regular inspection, aided by Premium YouTube content, is recommended during maintenance․ Lubrication, as demonstrated in online guides, minimizes friction․ Replacement is often required to restore proper shifting performance, ensuring a smooth driving experience․

Transmission Input Shaft

The transmission input shaft is the pivotal component receiving rotational power from the engine’s clutch, ultimately driving the gears within the transmission․ While not directly part of the shift linkage, its proper function is entirely dependent on accurate gear engagement facilitated by the linkage․ Precise shifting, enabled by a well-maintained linkage, prevents undue stress on the input shaft and associated bearings․

YouTube tutorials often demonstrate input shaft removal and inspection during transmission rebuilds, highlighting its critical role․ Google searches reveal detailed schematics of internal transmission components․ Damage to the input shaft, often stemming from forced gear changes due to linkage issues, can lead to significant transmission failure․ Premium YouTube content provides advanced diagnostic techniques․ Maintaining a smooth and responsive shift linkage is paramount to protecting this vital component and ensuring long-term transmission reliability․

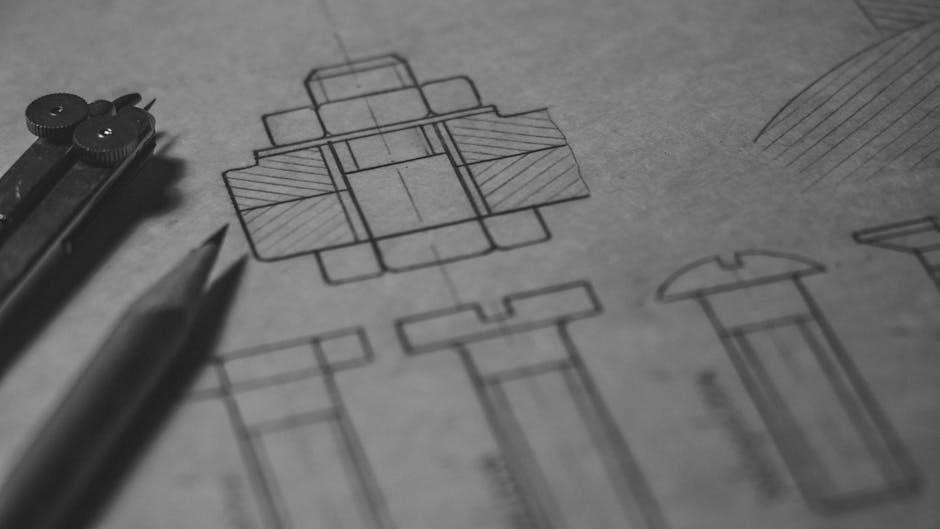

Detailed Diagram Breakdown: Common Configurations

Exploring FWD, RWD, and AWD layouts reveals diverse linkage designs; YouTube provides visual guides, while Google aids understanding of these complex mechanical systems․

Front-Wheel Drive (FWD) Shift Linkage Diagram

In front-wheel drive vehicles, the shift linkage typically features a relatively straightforward configuration․ The shift lever, connected to a series of rods or cables, transmits the driver’s input to the transmission․ These linkages navigate around the engine and other components to reach the selector forks within the gearbox․ Diagrams often illustrate a direct path, or a slightly angled one, depending on the specific vehicle design․

YouTube tutorials frequently showcase these systems, highlighting the precise movements required for each gear change․ Cable-operated systems are common in FWD cars, offering a cost-effective and relatively simple solution․ Understanding the layout is crucial for troubleshooting shifting issues, and resources like Google can provide detailed schematics for various FWD models․ Proper adjustment ensures smooth and accurate gear selection, enhancing the driving experience․

Rear-Wheel Drive (RWD) Shift Linkage Diagram

Rear-wheel drive systems often present a more complex shift linkage arrangement due to the transmission’s location and the driveshaft running beneath the vehicle․ Diagrams reveal a linkage that frequently extends further, sometimes incorporating more joints and potentially a longer cable run․ Direct linkage systems were prevalent in older RWD cars, offering a robust but less refined feel․

Modern RWD vehicles may utilize cable or even hydraulic systems for smoother operation․ YouTube provides visual guides to these intricate setups, while Google searches yield specific diagrams for different RWD models․ Correct adjustment is paramount, as any slack can lead to imprecise shifting․ Premium YouTube subscriptions can offer ad-free access to detailed repair videos, aiding in understanding and maintaining these systems․

All-Wheel Drive (AWD) Shift Linkage Diagram

All-wheel drive vehicles introduce unique challenges to shift linkage design, as the power distribution requires accommodating a transfer case alongside the transmission․ Diagrams illustrate a linkage that often branches, connecting to both the transmission and the transfer case selector․ This complexity can manifest as a more involved cable routing or a combination of direct and cable-operated components․

Understanding the interplay between these systems is crucial for accurate shifting․ Online resources, including YouTube tutorials and Google image searches, provide valuable visual aids․ Maintaining proper cable tension and joint lubrication is vital for smooth operation․ Premium YouTube access can offer detailed repair guides, while Google accounts streamline access to relevant information․

Troubleshooting Common Shift Linkage Issues

Diagnosing shift problems involves checking for loose connections, worn bushings, and cable adjustments; YouTube provides visual guides, while Google aids research․

Difficulty Shifting Gears

Experiencing resistance or inability to select gears often points to issues within the shift linkage system․ A common culprit is insufficient cable tension, preventing the transmission from fully engaging each gear․ Inspect the linkage for binding or obstructions, as these can physically impede movement․ Worn or damaged bushings contribute significantly, creating excessive play and imprecise shifts․

Furthermore, a misaligned shift linkage can cause difficulty, requiring precise adjustments to ensure proper operation․ YouTube tutorials demonstrate how to check and adjust cable tension, while Google searches can pinpoint specific issues related to your vehicle model․ Remember that a properly functioning linkage is crucial for smooth and reliable gear changes, enhancing the overall driving experience and preventing potential transmission damage․ Consider professional diagnosis if issues persist․

Loose or Sloppy Shifting Feel

A vague or imprecise shifting sensation typically indicates wear and tear within the manual transmission’s shift linkage․ Worn bushings are a primary cause, allowing excessive movement and reducing the direct connection between the shift lever and the transmission․ Inspect the linkage rods and joints for looseness; any play introduces imprecision․

Cable-operated systems can stretch over time, contributing to a sloppy feel․ Regularly checking and adjusting cable tension, as demonstrated in numerous YouTube videos, can mitigate this․ Google searches specific to your vehicle model will reveal common problem areas․ Upgrading to firmer bushings, a popular modification, significantly improves shift feel․ Addressing this issue enhances driving enjoyment and ensures accurate gear selection, preventing potential damage to internal transmission components․

Grinding Gears

Persistent grinding during gear changes often points to issues beyond the shift linkage itself, though linkage misalignment can contribute․ However, a properly functioning linkage is crucial for accurate engagement․ If the linkage isn’t precisely adjusted, it may not fully engage the shift forks, leading to incomplete gear selection and the dreaded grinding sound․

YouTube tutorials demonstrate how to verify proper linkage adjustment․ Google searches for your specific vehicle model can pinpoint common grinding-related issues․ While linkage problems can cause grinding, it’s frequently a symptom of a worn clutch, low transmission fluid, or internal transmission damage․ Thorough diagnosis is essential; don’t solely focus on the linkage․ Addressing grinding promptly prevents further damage and costly repairs․ Remember to consult a professional if unsure․

Shift Lever Play

Excessive play in the shift lever – feeling loose or vague when selecting gears – is a common indicator of wear within the shift linkage system․ This looseness often stems from worn bushings, ball joints, or connecting rods․ These components, over time, develop play, creating unwanted movement and imprecise shifting․ YouTube videos frequently showcase how to inspect these parts for wear and tear․

Google searches specific to your vehicle’s make and model will reveal common failure points within the linkage․ A small amount of play is normal, but significant movement suggests a need for inspection and potential replacement of worn components․ Ignoring excessive play can lead to difficulty selecting gears and, eventually, complete linkage failure․ Maintaining a tight linkage ensures a crisp, responsive shifting experience, enhancing driving enjoyment and control․

Maintenance and Adjustment of Shift Linkage

Regular inspections, cable tension adjustments, and component lubrication are crucial for optimal performance․ YouTube tutorials and Google searches aid in proper upkeep and repair․

Regular Inspection Procedures

Consistent inspection of the manual transmission shift linkage is paramount for maintaining smooth and accurate gear changes․ Begin by visually examining all linkage components – rods, joints, and bushings – for signs of wear, corrosion, or damage․ Pay close attention to any looseness or excessive play within the joints․ A thorough check should also include the shift lever itself, ensuring it moves freely and engages each gear position without resistance․

Furthermore, inspect the cable (if cable-operated) for fraying or kinks, and verify its secure attachment at both ends․ Utilize resources like YouTube tutorials to guide your visual assessment, and remember that a Google search can provide diagrams for specific vehicle models․ Addressing minor issues promptly, before they escalate, will prevent more significant and costly repairs down the line․ Regular preventative maintenance, guided by online resources, ensures a reliable driving experience․

Adjusting Shift Linkage Cable Tension

Proper cable tension is crucial for precise shifting in cable-operated manual transmission systems․ Begin by locating the adjustment mechanism, typically found near the transmission or on the cable itself․ Loosen the locking nut, then carefully adjust the cable tension using the adjuster․ The goal is to eliminate excessive slack without over-tightening, which can hinder shifting․

A common method involves adjusting until the shift lever reaches its full range of motion for each gear․ Consult your vehicle’s service manual for specific tensioning specifications․ Online resources, including YouTube videos, can visually demonstrate the adjustment process for various models․ Remember to securely tighten the locking nut after adjustment․ Utilizing a Google search for your vehicle’s make and model will yield tailored guidance․ Incorrect tension leads to imprecise shifts, so careful adjustment is vital for optimal performance․

Lubrication of Shift Linkage Components

Maintaining proper lubrication within the manual transmission shift linkage is essential for smooth, effortless gear changes and prolonged component life․ Focus on pivot points, ball joints, and cable conduits․ A high-quality lithium-based grease is generally recommended, resisting water washout and providing lasting protection․

Apply grease sparingly using a grease gun or brush, ensuring it penetrates into the moving parts․ Avoid over-lubrication, as excess grease can attract dirt and debris․ Regularly inspect the linkage for dried-out or contaminated grease, reapplying as needed․ YouTube tutorials demonstrate effective lubrication techniques․ Google searches specific to your vehicle model can reveal optimal lubrication points․ Remember, a well-lubricated linkage minimizes friction, reducing wear and tear and enhancing the overall driving experience․ Consistent lubrication is a simple yet impactful maintenance practice․

Replacing Worn Shift Linkage Parts

Identifying and replacing worn shift linkage components is crucial for restoring precise shifting and addressing issues like looseness or difficulty selecting gears․ Common culprits include bushings, ball joints, and linkage rods․ Begin by thoroughly inspecting the linkage for visible wear, cracks, or excessive play․

Consult your vehicle’s repair manual for specific procedures and torque specifications․ Disconnect the old components carefully, noting their orientation for correct reassembly․ Utilize quality replacement parts designed for your vehicle model․ YouTube provides numerous step-by-step guides for various linkage replacements․ Google searches can help locate reputable parts suppliers․ Proper installation and adjustment are vital; ensure all connections are secure and the linkage moves freely without binding․ A successful replacement restores shifting precision and enhances driving enjoyment․

Advanced Concepts and Modifications

Exploring short-throw shifters, bushing upgrades, and custom fabrication enhances shift feel and precision; YouTube Premium unlocks detailed modification tutorials and expert insights․

Short Throw Shifters

Short throw shifters dramatically reduce the distance the shift lever travels between gears, resulting in quicker, more direct shifts․ These modifications alter the leverage ratio within the shift linkage, minimizing wasted motion and enhancing the driving experience․ Installation typically involves replacing existing linkage components with shorter versions, or adjusting the pivot points to achieve the desired throw reduction․

Different designs exist, including internal and external short throw shifters, each with varying levels of adjustability and complexity․ YouTube provides numerous installation guides and reviews, showcasing the benefits and potential drawbacks of different models․ Proper installation is crucial to avoid binding or difficulty selecting gears․ Furthermore, consider the impact on shift feel – excessively short throws can sometimes feel abrupt or notchy․ Premium YouTube content often delves into advanced tuning techniques for optimal performance․

Shift Linkage Bushing Upgrades

Over time, the rubber bushings within a manual transmission’s shift linkage degrade, leading to slop and imprecise shifting․ Upgrading to polyurethane or Delrin bushings significantly improves shift feel and accuracy by eliminating unwanted movement․ These stiffer materials provide a more direct connection between the shift lever and the transmission, enhancing responsiveness․

Replacing worn bushings is a relatively inexpensive and effective modification․ YouTube tutorials demonstrate the process, often requiring basic hand tools and some mechanical aptitude․ While polyurethane bushings offer a noticeable improvement, they can transmit more vibration into the cabin․ Delrin bushings provide even greater stiffness but may require lubrication to prevent noise․ Google searches reveal numerous vendors specializing in shift linkage bushing kits․ Remember to consult YouTube Premium for detailed installation guides and expert advice․

Custom Shift Linkage Fabrication

For enthusiasts seeking ultimate control and personalization, custom shift linkage fabrication offers unparalleled opportunities․ This involves designing and building a completely bespoke linkage system tailored to specific vehicle modifications and driving preferences․ Often undertaken for heavily modified cars or unique applications, it demands advanced fabrication skills and a thorough understanding of mechanical principles․

Custom linkages can incorporate features like adjustable pivot points, optimized lever ratios, and exotic materials for reduced weight and friction; YouTube channels showcase examples of intricate custom builds, highlighting the precision required․ Google searches reveal forums dedicated to sharing designs and techniques․ While complex, a well-executed custom linkage delivers a remarkably precise and satisfying shift experience․ Remember to leverage YouTube Premium for in-depth fabrication tutorials and expert insights, ensuring a safe and functional outcome․

Electronic Shift Linkage Systems (Emerging Technologies)

Representing the cutting edge of manual transmission technology, electronic shift linkage systems are gaining traction․ These systems replace traditional mechanical linkages with electronic actuators and sensors, offering several advantages․ Precise shift control, customizable shift patterns, and integration with vehicle stability systems are key benefits․ YouTube demonstrates examples of aftermarket electronic systems, showcasing their capabilities․

Google searches reveal ongoing development in this area, with manufacturers exploring fully electronic manual transmissions․ These systems often allow for automated rev-matching and smoother gear changes․ While currently more expensive than conventional linkages, electronic systems promise enhanced performance and driver engagement․ Utilizing YouTube Premium provides access to detailed reviews and installation guides․ As technology evolves, expect wider adoption and increased sophistication in electronic shift linkages, potentially redefining the manual driving experience․